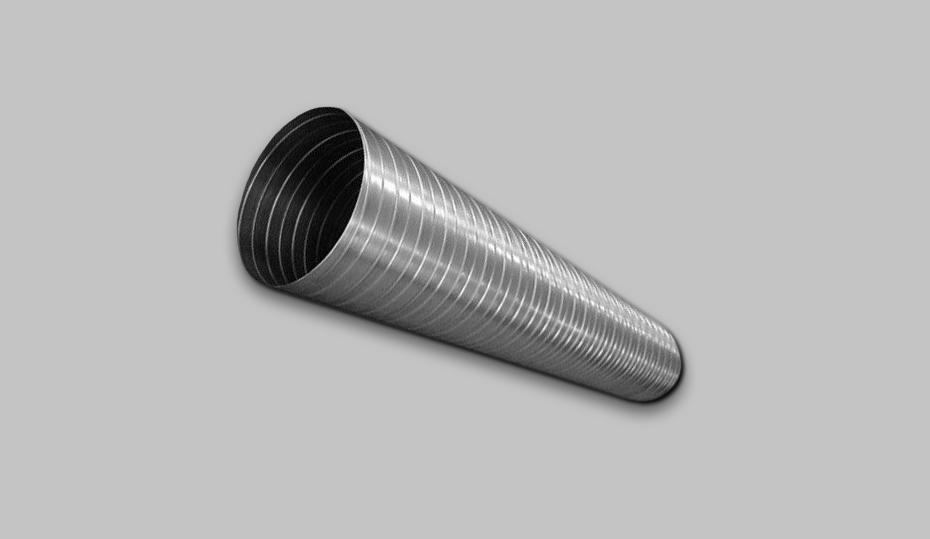

In the world of industrial piping , the choice of materials and construction methods can significantly impact a project's success. Spiral pipes, sometimes referred to as spiral tubes or spiral seam pipes, have emerged as a versatile and efficient solution for a wide range of applications. Nufit Piping Solutions, a leader in the field, offers a comprehensive range of spiral pipes that provide numerous advantages over traditional welded or seamless pipes.

The five key benefits of spiral pipes, particularly spiral stainless steel pipe, and why Nufit Piping Solutions is the go-to provider.

1. Exceptional Strength and DurabilitySpiral pipes are manufactured using a unique process where a continuous strip of metal is formed into a helix and then welded along the spiral seam. This construction method creates a pipe with superior strength and durability compared to welded pipes with longitudinal seams. The spiral seam distributes stress more evenly, reducing the risk of failure under high pressure or extreme conditions.

2. Enhanced Flexibility and AdaptabilityOne of the standout features of spiral pipes is their inherent flexibility. The helical structure allows for greater bending and adaptability, making them ideal for applications that require complex piping layouts or frequent changes in direction. This flexibility reduces the need for additional fittings and joints, simplifying installation and lowering costs.

3. Cost-EffectivenessSpiral pipes offer significant cost advantages over traditional seamless pipes. The manufacturing process is more efficient, resulting in lower production costs. Additionally, the reduced need for fittings and the ease of installation further contribute to overall cost savings. This makes spiral pipes an attractive option for projects with budget constraints.

4. Versatility in ApplicationsSpiral pipes' adaptability and strength make them indispensable across various industries :

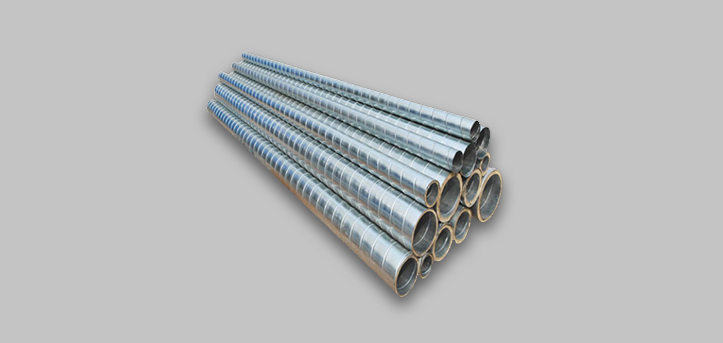

Nufit Piping Solutions stands out for its commitment to customization and quality assurance. We offer a wide range of spiral pipe sizes and materials, including carbon steel, stainless steel, and various alloys, to meet the specific needs of each project. Their state-of-the-art manufacturing facilities and stringent quality control processes ensure that every spiral pipe meets or exceeds industry standards.

Nufit Piping Solutions has earned a reputation for delivering high-quality spiral pipes that meet the most demanding requirements. Our team of experts works closely with clients to understand their unique needs and provide tailored solutions. With a focus on innovation, reliability, and customer satisfaction, Nufit Piping Solutions is the trusted choice for spiral pipe solutions.

Spiral pipes, especially spiral stainless steel pipes, offer a compelling combination of strength, flexibility, cost-effectiveness, and versatility. Nufit Piping Solutions commitment to quality and customization makes us the ideal partner for any project requiring spiral pipe solutions.

If you're looking for reliable, efficient, and cost-effective piping solutions, look no further than Spiral Pipes by Nufit Piping Solutions.

Ready to elevate your piping systems? Contact us at sales@nufitalloys.com today! Our experts will help you find the perfect Spiral Pipes to achieve your project goals.