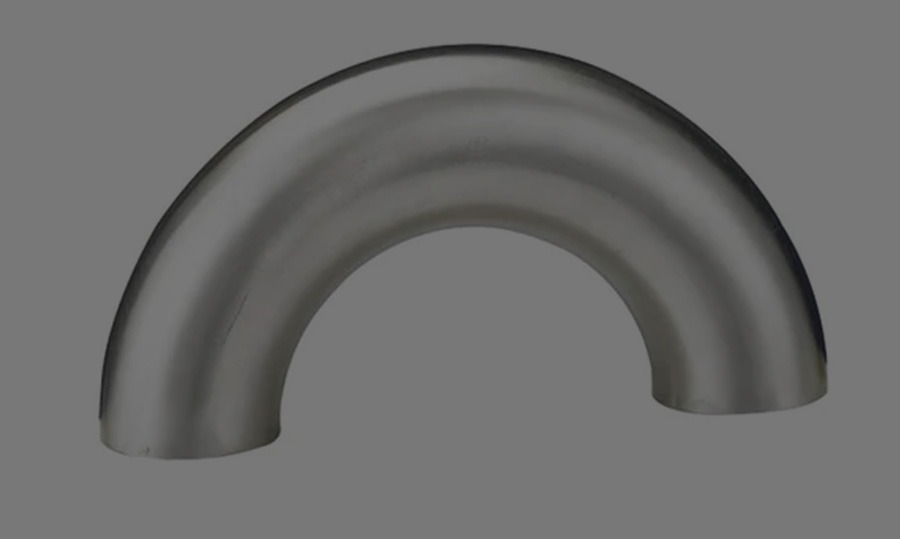

The buttweld 180 degree long radius elbow is a crucial element in piping systems designed to change the direction of flow by 180 degrees whilst preserving clean transitions and decreased stress drops. These fittings are extensively utilized in industries along with petrochemicals, oil and gasoline, energy generation, and water treatment. Understanding the right method for connecting a buttweld 180 degree long radius elbow to a pipe is crucial for ensuring the integrity, safety, and performance of the piping device.

Overview of Buttweld 180 Degree Long Radius Elbow

A buttweld 180 degree long radius elbow is characterized by its extended curvature, which provides a smooth flow path and minimizes resistance. This fitting is typically used in situations where space constraints require a compact design without compromising flow efficiency. The key features include :

- Long Radius Design : The radius of the curve is typically 1.5 times the nominal diameter of the pipe, ensuring smoother flow transitions.

- Standard Dimensions : The 180 degree long radius elbow dimensions adhere to international standards such as ASME B16.9, ensuring compatibility across various applications.

- Material Options : Available in materials like carbon steel, stainless steel, and alloy steel, these elbows cater to a wide range of industrial needs.

Connection Method to Pipe

Connecting a buttweld 180 degree long radius elbow to a pipe involves several crucial steps to ensure a secure and leak-proof joint. Here’s a step-by-step guide

1. Preparation

- Inspection : Check the buttweld 180 degree long radius elbow fittings for any defects or irregularities. Ensure the pipe and elbow are free from dirt, grease, or corrosion.

- Measurement : Verify the 180 degree long radius elbow dimensions to confirm compatibility with the pipe diameter and wall thickness.

- Cutting the Pipe : Use a pipe cutter or saw to achieve a clean, perpendicular cut on the pipe end.

2. Alignment

- Positioning : Place the buttweld 180 degree long radius elbow in alignment with the pipe. Use alignment tools such as clamps or tack welds to hold the components in position.

- Gap Consideration : Maintain a small gap between the pipe and the elbow to ensure proper penetration of the welding material.

3. Welding Process

The welding process is the most critical part of the connection method. A proper weld ensures the joint’s structural integrity and leak resistance.

- Tack Welding : Perform tack welds at multiple points to hold the buttweld 180 degree long radius elbow fittings in place.

- Full Welding : Use a qualified welder and an appropriate welding technique, such as TIG or MIG welding, to create a continuous weld around the joint. Ensure the weld is uniform and free from voids or inclusions.

- Inspection : After welding, conduct non-destructive testing (NDT) methods, such as radiographic or ultrasonic inspection, to verify the weld quality.

4. Post-Weld Treatment

- Cleaning : Remove slag, spatter, or other residues from the welded area.

- Heat Treatment : In some cases, post-weld heat treatment (PWHT) may be required to relieve stresses and enhance the joint's mechanical properties.

- Painting and Coating : Apply corrosion-resistant coatings if the piping system is exposed to harsh environments.

Advantages of Proper Connection

- Leak Prevention : Ensures a tight seal, reducing the risk of leaks.

- Longevity : Properly connected buttweld 180 degree long radius elbow fittings last longer under operational stresses.

- Efficiency : Maintains smooth flow, reducing pressure losses and energy costs.

- Compliance : Adherence to standards ensures safety and reliability in critical applications.

Applications of Buttweld 180 Degree Long Radius Elbow

The buttweld 180 degree long radius elbow is used in a variety of industries due to its adaptability and performance benefits. Some applications include :

- Chemical Processing : To manage corrosive flows and high temperatures.

- Oil and Gas : In refineries and offshore platforms where compact and efficient piping layouts are crucial.

- Power Plants : To handle steam and high-pressure conditions.

Conclusion

Connecting buttweld 180 degree long radius elbow to a pipe requires careful preparation, precise alignment, and skilled welding techniques. By adhering to these practices, industries can make certain the sturdiness and performance in their piping systems. With its standardized 180 degree long radius elbow dimensions and robust design, this becoming stays a desired choice for annoying packages.

Nufit Flanges, a leading manufacturer, supplier, and exporter primarily based in Mumbai, India, offers premium-quality buttweld 180 degree long radius elbow fittings to fulfill diverse commercial requirements. For inquiries or customized solutions, experience free to contact us today.