Offshore platforms, engineering marvels in the most hostile conditions, require parts that can withstand high pressures, salt water, heat, cold, and the ravages of time. Forged fittings have emerged as the best solution to these conditions due to their strength, durability, and reliability as compared to conventional fittings.

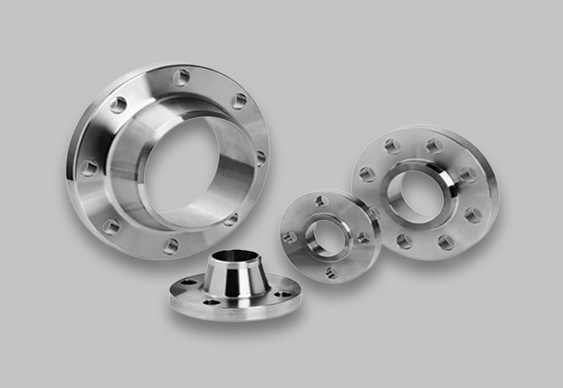

Forged pipe fittings are not cast or fabricated but are made by heating metal and then pressing it under high pressure. This forging realigns the internal structure of the metal, and hence the components produced are of higher mechanical quality. These fittings are stronger, tougher, and more fatigue-resistant than fittings made by other processes.

Offshore platforms are characterized by certain conditions that require the use of hard-wearing and durable components. Pressure due to the depth of water, corrosiveness of water, and fluctuating temperature are some of the factors that affect the stability of the piping system. Forged fittings address these challenges by providing: These challenges are met by forged fittings through the following ways

Severe conditions at offshore locations demand the use of hard-wearing materials. Carbon steel (A105) is widely used for standard fittings because of its relatively low cost and acceptable strength. Stainless steel (316/316L) is used for corrosion resistance which is very important in such applications. In extreme circumstances, materials such as nickel alloys or chrome-moly steels are used. Particular grades and standards guarantee the application in the offshore field.

Offshore safety and efficiency cannot be achieved without forged fittings. Their strength and fatigue endurance enable them to endure the pressure from the environment. Precision manufacturing is used to ensure that the seals are very tight, thus reducing leakage in dangerous systems. This means that their lifespan is longer, thus fewer replacements, less time off, and the associated costs.

Cast fittings are cheaper but weaker and not suitable for offshore stress. Adaptable as fabricated fittings may be, they are usually welded, and this can create areas of weakness. Forged fittings are stronger and more reliable than other types of fittings, which is why they are used.

Rigorous inspection is crucial. Visual inspection is the process of examining the surface of an object for defects. Liquid Penetrant Testing is used to detect very small defects. Magnetic Particle Inspection is used to detect surface and near-surface irregularities in ferromagnetic materials. Ultrasonic Testing is used for the detection of internal defects and measurement of thickness of the wall. The frequency of inspection varies with the regulation, the type of fitting, and the severity of the environment.

Thus, due to the combination of unmatched strength, durability, precision, and versatility, forged fittings have become the most suitable for offshore platforms. This is due to their high tolerance to conditions such as high pressure and temperature, low risk, and high reliability, which makes them an essential tool in the search for safe and efficient operations in the offshore industry

At Nufit Flanges, we supply forged fittings that are suitable for use in offshore environments due to their excellent quality. Our forged steel pipe fittings forged threaded fittings, and ASTM A182 fittings are some of the best in the market owing to their performance, durability, and safety

As you know, each project is individual in terms of the offshore company, which is why we provide an individual approach. Our company’s specialists will help you to make the right choice of the necessary fittings for your application

Contact us today at sales@nufitalloys.com to learn more about how our forged fittings can enhance the safety, reliability, and efficiency of your offshore operations.