Fasteners are fundamental components in the world of construction and manufacturing, providing the necessary connections to hold various materials together. From skyscrapers to everyday household items, fasteners play a critical role in ensuring the integrity and functionality of countless applications. This comprehensive guide by Nufit Piping Solutions delves into the intricacies of industrial fasteners, exploring their types, uses, and the importance of choosing the right fasteners company. Let's embark on a journey to understand these indispensable elements better.

Understanding Fasteners

Types of Fasteners

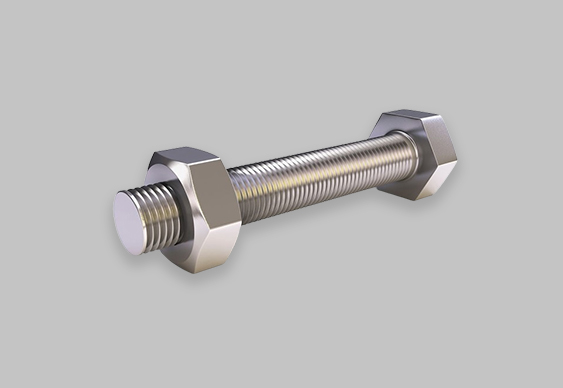

- Bolts : These are externally threaded fasteners designed for insertion through holes in assembled parts. They are secured with nuts and are used when a high level of clamping force is needed. Industrial bolts are prevalent in construction, automotive, and heavy machinery applications.

- Screws : Similar to bolts but typically used without nuts, screws have a helical ridge that provides superior holding power in materials like wood, metal, and plastic. They are used in a variety of applications, from cabinetry to electronic devices.

- Nuts : These are internally threaded fasteners used in conjunction with bolts to secure two or more parts together. Nuts come in numerous styles, including hexagonal, square, and wing nuts, each designed for specific purposes.

- Washers : These are thin plates with a hole in the middle, used to distribute the load of a threaded fastener like a screw or bolt. Washers prevent damage to the surfaces being fastened and reduce the risk of loosening due to vibration.

- Rivets : These fasteners consist of a cylindrical shaft with a head on one end. Rivets are used when a strong, permanent bond is required, such as in the assembly of aircraft and structural steel frameworks.

Importance of Choosing the Right Industrial Fasteners

Selecting the correct industrial fasteners is crucial for the success and longevity of any project. Here’s why

- Safety and Stability : The wrong fastener can compromise the safety and stability of a structure or device, leading to potential failures and hazards.

- Durability : Properly chosen fasteners enhance the durability of the assembly, ensuring it withstands various stresses and environmental conditions over time.

- Cost-Effectiveness : Using the right fasteners from the outset can save money by preventing future repairs, replacements, or maintenance.

- Efficiency : The correct fasteners can streamline the assembly process, saving time and labor costs.

Factors to Consider When Selecting Fasteners

When choosing industrial fasteners, several factors must be taken into account.

- Material : Fasteners are made from various materials, including steel, stainless steel, brass, and titanium. The choice depends on the application requirements such as strength, corrosion resistance, and weight.

- Size and Length : The dimensions of the fastener must be compatible with the components being joined. This ensures a secure fit and proper load distribution.

- Thread Type : Threads can be coarse or fine, with each type offering different benefits. Coarse threads are more resistant to stripping, while fine threads provide a tighter fit.

- Plating and Coating : Fasteners can be plated or coated to enhance their resistance to corrosion, wear, and extreme temperatures. Common coatings include zinc, cadmium, and galvanizing.

- Environmental Conditions : Consider the environment where the fasteners will be used. Exposure to moisture, chemicals, or extreme temperatures can affect the performance and longevity of the fasteners.

Why Choose a Reputable Fasteners Company?

Partnering with a reliable fasteners company like Nufit Piping Solutions offers several advantages.

- Quality Assurance : Reputable manufacturers ensure their products meet stringent quality standards, providing peace of mind and reliability.

- Expertise and Guidance : Experienced companies can offer valuable advice on the best fasteners for specific applications, helping you make informed decisions.

- Wide Range of Products : Established manufacturers provide a broad selection of fasteners, ensuring you find the right fit for your needs.

- Customization Options : Leading companies offer customized fastener solutions tailored to unique project requirements.

The Role of Manufacturers of Fasteners

Manufacturers of fasteners play a crucial role in the supply chain, ensuring the availability of high-quality products designed to meet diverse industrial needs. These manufacturers invest in research and development to innovate and improve fastener technologies, enhancing performance and reliability.

Key Contributions of Fastener Manufacturers

- Innovation : Continuous R&D efforts lead to the development of advanced fasteners that meet evolving industry demands, such as lightweight yet strong materials and environmentally friendly coatings.

- Standards Compliance : Manufacturers adhere to international standards and certifications, ensuring their products meet safety and quality benchmarks.

- Bulk Supply : Fastener manufacturers can supply large quantities of fasteners, supporting large-scale projects and industries with consistent and reliable inventory.

- Technical Support : They provide technical support and documentation, helping customers understand the proper use and installation of their products.

Conclusion

Fasteners are indispensable in the assembly and construction of countless products and structures. Understanding the types, uses, and selection criteria for industrial fasteners is essential for ensuring safety, durability, and efficiency in any project. Partnering with a reputable fasteners company like Nufit Piping Solutions can provide access to high-quality products, expert advice, and reliable supply chains. By paying careful attention to the material, size, thread type, and environmental conditions, you can select the right fasteners for every need, ensuring the success and longevity of your assemblies

Ready to elevate your piping systems? Contact us at sales@nufitalloys.com today. Our experts will help you find perfect Fasteners to achieve your project goals.