In the area of piping systems, flanges are among the most important elements which offer a secure and easy way of connecting and disconnecting pipelines. Regardless of the type of industrial, commercial, or residential piping systems you are dealing with, it is crucial to learn about the various connection methods of flanges to improve your projects’ productivity and safety. In this blog, five.

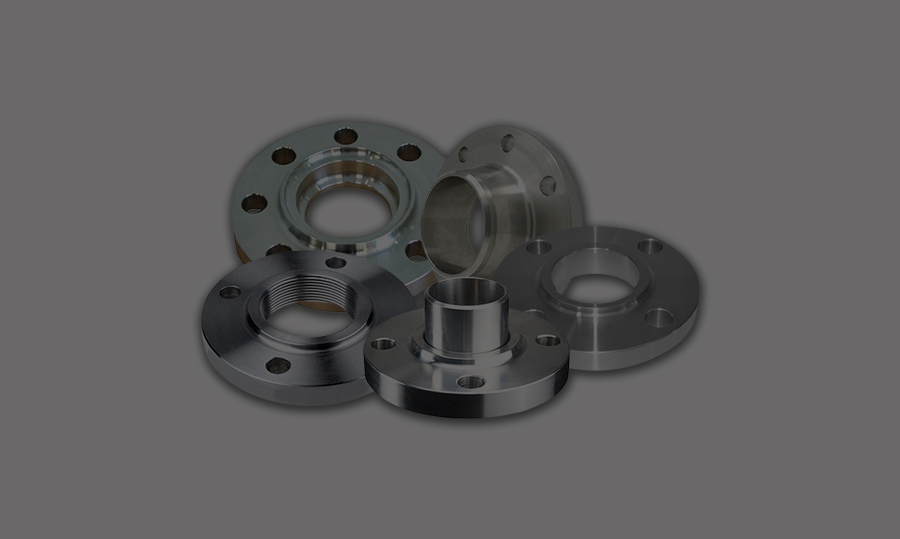

Welding neck flanges are generally applied in high-pressure applications and are considered to be the most suitable for use in critical services. This flange type has a long tapering hub that is longer than that of the standard types of flanges and offers more support. The flange is then welded to the pipe and this makes the connection to be very strong and tight.

AdvantagesThe slip-on flange is one of the most commonly used and economical flanges for most of the piping systems. This flange type is slipped over the pipe and then welded to it, which is quite self-explanatory from the name. Slip-on flanges are also less complicated than welding neck flanges because there is no need to align the two very closely.

Advantages

Socket weld flanges are used in small bore, high pressure piping systems. One part of the pipe is fitted into the socket end of the flange and then the weld is made around the outer surface. It gives a very good and tight connection.

AdvantagesThreaded flanges are one of the non-welding flange fittings that are used to connect flange parts. The pipe and flange are threaded and this is suitable for systems that are often disassembled or require regular maintenance.

AdvantagesLap joint flanges are used with a stub end, which makes for a very versatile and easy to maintain type of connection. The flange is not fixed to the pipe by welding but by the bolted joint and this makes it easy to rotate and align.

AdvantagesIt is crucial to know the different connection methods of flanges to be in a position to choose the right one for your piping system. Welding neck flanges are strong and are used in places where high pressure is applied while lap joint flanges are flexible. Thus, when selecting a connection method, one can guarantee the reliability, durability, and functionality of the piping systems

Time spent learning these connection techniques will not only enhance the projects you are working on but also guarantee compliance with the set standards. Whether it is industrial pipelines that require high pressure or the residential systems that require low pressure, the right flange fittings will do the work

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more information about flanges, and how to use it in your systems.