In the realm of industrial systems, the need for reliable and efficient connections is paramount. One crucial component that ensures the seamless integration of pipelines and equipment is the plate flange. These versatile and essential fittings play a vital role in various industries, enabling secure and efficient flow within complex systems. In this blog, we will explore the significance of plate flanges, their applications, benefits, and the role of plate flanges manufacturers and plate flanges suppliers in maintaining industrial efficiency.

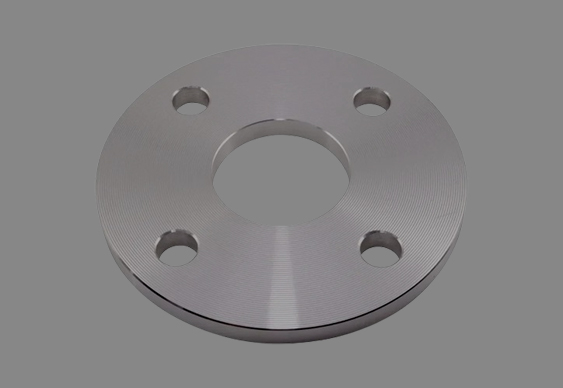

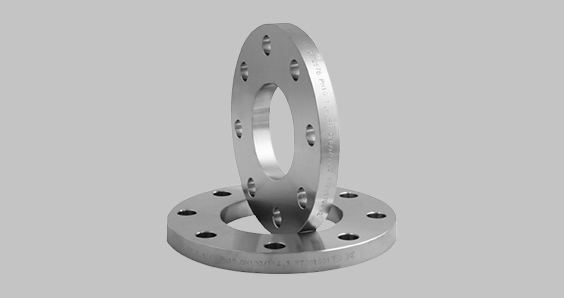

Plate flange is a flat, circular disk that has no holes in the center and it can be attached to the end of pipes. They offer a way to both disconnect and reconnect pipelines, which simplifies any maintenance or repair. Plate flanges usually weld or are screwed into place but also can be manufactured to take a slip fit with O-Ring Seals.

There are several types of plate flanges available, each designed to meet specific needs and applications.

The use of plate flanges in industrial systems offers numerous benefits

Versatility : Plate flanges can be obtained in various material grades, sizes, and configurations to match varied types of applications. These can be tailor-made to particular necessities, making your application compatible with different systems.

Strength and Durability : Plate flanges are made from materials including stainless steel, carbon steel, and alloy steel. They are designed to handle high pressure, temperature, and corrosive environments for durable service life.

Simple Installation and Maintenance : Flanges support easy installation and maintenance. They can be mobilized rapidly and disassembled for quick repair, replacement, or inspection. This minimizes downtime to keep industrial systems running.

No Leaking Connections : When you install plate flanges correctly, they provide a good, strong, air- and water-tight connection. This is of great importance, especially in industries where leak prevention is crucial for safety and environmental protection.

Cost-Effective : Plate flanges are a cost-effective solution for connecting pipes and equipment. Their durability and ease of maintenance play a crucial part in terms of lowering costs as well as improving operational efficiency.

Plate flanges are integral components in various industrial systems, including Plate flanges are integral components in various industrial systems, including

Plate flanges offer significant advantages in terms of maintenance: Plate flanges offer significant advantages in terms of maintenance

Plate flanges can be customized to meet specific requirements: Plate flanges can be customized to meet specific requirements

These aspects highlight the flexibility and customization of plate flanges in industries where flexibility and ease of maintenance are key aspects that determine the effectiveness of the flanges in the industries

The quality and reliability of plate flanges depend significantly on the expertise and capabilities of plate flanges manufacturers and plate flanges suppliers. These entities play a crucial role in ensuring that industries receive high-quality flanges fittings that meet stringent standards and specifications

Plate Flanges Manufacturers : Plate flanges manufacturers are responsible for producing plate flanges that adhere to industry standards and customer requirements. They use advanced manufacturing techniques and quality control processes to ensure the flanges' strength, durability, and precision. By choosing a reputable plate flanges manufacturer, industries can be assured of receiving products that perform reliably in demanding conditions.

Plate Flanges Suppliers : Plate flanges suppliers are essential in the distribution and availability of plate flanges to various industries. They maintain a wide inventory of flanges, ensuring that customers can access the right products promptly. Reputable plate flanges suppliers provide technical support, helping customers select the appropriate flanges for their specific applications. They also offer competitive pricing and timely delivery, contributing to the overall efficiency of industrial operations.

In conclusion, plate flanges are indispensable components in industrial systems, providing reliable and secure connections for pipes and equipment. Their versatility, strength, and ease of maintenance make them a preferred choice across various industries. Understanding the different types of plate flanges and their applications helps in selecting the right fittings for specific needs

The role of plate flanges manufacturers and plate flanges suppliers cannot be overstated. Their expertise and commitment to quality ensure that industries receive high-performance plate flanges that meet stringent standards. By partnering with reputable manufacturers and suppliers, industries can achieve efficient and leak-proof plate flanges pipe joints, contributing to the overall success of their operations

Whether you are in the oil and gas, chemical processing, power generation, water treatment, or manufacturing industry, investing in high-quality plate flanges from trusted suppliers ensures the reliability and efficiency of your systems

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more information about the plate flanges, and how you can utilise them in plant operations.