In the industrial realm, the integrity of piping systems is paramount. A crucial component of these systems is the pipe nipple, specifically the buttweld pipe nipple. These fittings serve as essential connectors within piping networks, facilitating the flow of liquids, gases, and other substances. Understanding the quality of buttweld pipe nipple fittings can be the difference between a highly efficient system and one prone to leakage and failure. Here’s a comprehensive guide to identifying high-quality buttweld pipe nipple products, presented by Nufit Flanges.

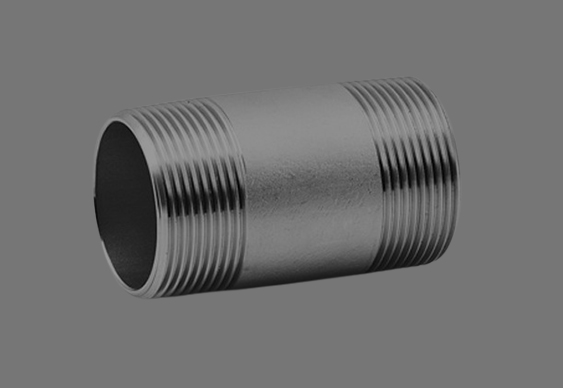

Before we get into the quality indicators let's understand what a pipe nipple is. A pipe nipple is a short length of pipe with male pipe threads at both ends, usually used to connect other fittings. Buttweld pipe nipple fittings, on the other hand, are made specifically for welding in place which forms a permanent and very substantial connection.

The first signs that a welding bottle nozzle is of good quality are generally in the material. A solid material such as stainless steel, carbon steel, or alloy steel is the only type of pipe nipple that can be soldered and withstand high pressure and corrosive environments. Make sure that the product complies with Market and Material certifications

Quality pipe nipple fittings meet a series of quality manufacturing standards. Choose products that are certified by organizations like ASTM, ANS, or other relevant standards. Some of these standards are there to make sure that the products are going to be responsive to the pressure and temperatures that they may face in an industrial environment

The thickness of a buttweld pipe nipple wall is dependent on the durability and quality. Foam with thicker walls resists greater pressures and is less likely to distort or fracture under such conditions. Be sure to confirm this thickness will work for your specific project

Because buttweld pipe nipple fittings are designed to be welded directly to other pipes, they should be easy to weld. The high-quality nipples will come free of oils, rust, or contaminants that degrade the weld. Uniformly preparing the bevel end of an outlet using it directly results in far easier and stronger welds

High-quality buttweld pipe nipples should have precise dimensions to ensure a tight fit and prevent leaks. Measurements such as length, diameter, and thread pitch should be accurate and consistent across all units. This precision ensures reliable integration into the existing piping system without the need for additional adjustments or modifications

A smooth surface finish is not only about aesthetics; it also affects the performance of the pipe nipple. A well-finished nipple minimizes resistance to fluid flow and reduces the likelihood of corrosion. Check for a uniform, smooth finish without any signs of pitting or irregularities

Each high-quality buttweld pipe nipple should come with proper markings for traceability. These markings typically include the manufacturer's name, material grade, size, and heat number. This information is crucial for maintaining the quality control of the installations and for future maintenance or replacement work.

While it might be tempting to opt for cheaper options, high-quality buttweld pipe nipple fittings often come at a higher initial cost which can lead to longer service life and fewer system failures. Investing in quality upfront can reduce long-term operational costs significantly

Selecting the right buttweld pipe nipple involves careful consideration of various quality indicators. By ensuring that the nipples you purchase meet all the above criteria, you can significantly enhance the reliability and efficiency of your piping systems. Nufit Flanges remains committed to providing top-quality products that meet the needs of our demanding industrial landscape. Whether you are constructing a new system or upgrading an existing one, choosing the right components can make all the difference in its overall performance and longevity

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more information about the Buttweld Pipe Nipples, and how you can utilise them in your operations.