Forged pipe caps in high-pressure environments

When you're designing or maintaining piping systems that handle intense pressures, selecting the right end caps, like forged caps, transcends a simple choice of accessories. It becomes a fundamental decision impacting both safety and efficiency. Forged pipe caps, including forged threaded caps that often align with ASME B16.11 standards, offer superior strength and reliability compared to cast alternatives. Thus, the ASME B16.11 threaded cap fitting makes an ideal choice for demanding high-pressure operations. Nufit Piping Solutions understands these critical needs and helps you secure your operations by providing a range of high-quality forged fittings engineered to withstand the rigors of your high-pressure systems.

The Forged Advantage

The forging process fundamentally transforms the metal used to create pipe caps. By applying immense heat and pressure, steel is shaped while its grain structure becomes refined and uniform. This results in several benefits critical for high-pressure environments :

- Immense Tensile Strength : The forging process endows pipe caps with exceptional tensile strength. This allows them to resist the internal forces generated by high-pressure fluids within the system, minimizing the risk of catastrophic leaks or failures that could pose safety hazards.

- Enhanced Toughness : Forging enhances the toughness of the metal used in pipe caps. This means they are less prone to cracking or becoming brittle, even when subjected to the mechanical stresses or temperature fluctuations common within high-pressure piping systems.

- Resistance to Corrosion : The forging process creates a dense, refined grain structure within the steel used for pipe caps. This enhanced structure provides improved resistance to the corrosive effects of aggressive fluids often encountered in high-pressure environments, ensuring the long-term integrity of the cap and overall system.

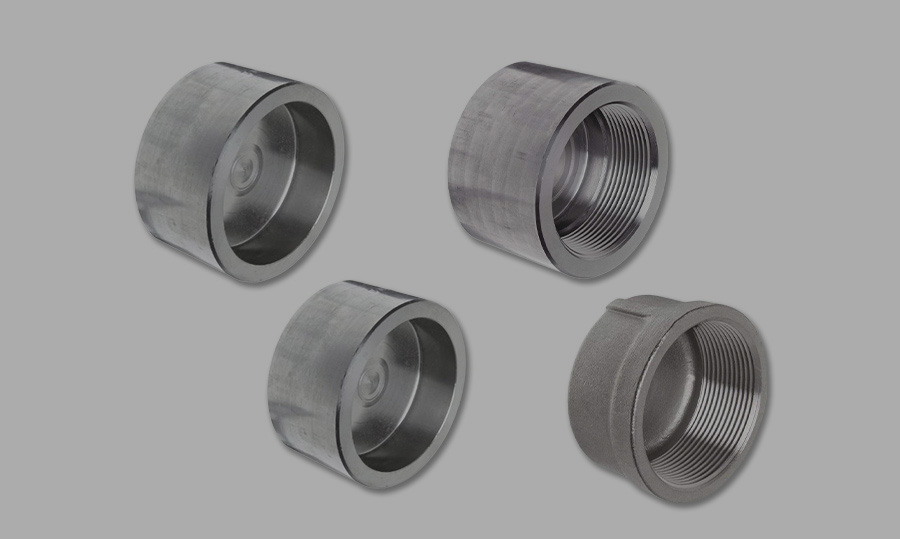

Types of Forged Pipe Caps used in High Pressure Environments

Nufit Piping Solutions understands that your high-pressure system has unique needs. We offer several types of forged caps to meet various demands :

- Forged Threaded Caps : These feature internal threads for a secure connection, ideal for terminating pipelines where ease of access is important. They comply with the ASME B16.11 standard, ensuring quality and compatibility.

- Forged Socket Weld Caps : Offering a permanent, leak-tight seal by welding the cap directly to the pipe. Often used in applications with extremely high pressure or where vibrations are a concern.

- Specialty Caps : Customization options exist, such as adding drain ports or pressure gauge connections if your system requires them.

Pressure Rating of Forged Pipe Caps

- Material : The type of metal used to construct a forged pipe cap significantly impacts its pressure rating. Stainless steel, carbon steel, and various alloy steels possess different strength characteristics. Choosing a material with the appropriate strength properties is essential for a given pressure application.

- Class : Forged pipe caps are categorized into classes, such as 2000#, 3000#, 6000#, and 9000#. These class designations indicate the maximum pressure the cap can safely withstand, with higher numbers corresponding to higher pressure limits.

- Size and Wall Thickness : The physical dimensions of a forged pipe cap play a crucial role in its pressure capabilities. Generally, larger caps with thicker walls can handle higher pressures than smaller caps with thinner walls. This is due to the increased material present to resist the internal forces generated by the pressurized fluid.

Key Considerations for Selecting Forged Pipe Caps

- Pressure Rating : This rating indicates the maximum internal pressure the cap can safely withstand without leaking or failing. It's crucial to choose a cap with a pressure rating that meets or exceeds the maximum operating pressure of your piping system. Underestimating pressure ratings can lead to catastrophic failures, so always exercise caution.

- Material Compatibility : Consider the specific chemicals, their concentrations, and any potential for abrasive particles in the flow. Stainless steel offers broad resistance to many corrosive substances, while various alloy steels may be needed for highly specialized applications. Selecting a compatible material prevents corrosion, ensuring the cap's longevity and the safety of your system.

- Connection Type : Threaded caps provide ease of installation and removal, making them suitable for temporary setups or sections of the system requiring frequent maintenance. Socket weld caps offer a secure, permanent seal ideal for critical applications where leaks are unacceptable. Other specialty connections, like flanged or buttweld caps, may be required for specific configurations or particularly high-pressure systems.

- Temperature Range : The operating temperature range of your system is vital in selecting the right forged cap. Different metals and alloys have varying tolerances for both high and low temperatures. Temperature fluctuations can cause expansion and contraction, placing stress on the pipe cap. Ensure the selected cap can handle the full temperature range expected within your system to avoid failures from thermal stress.

- Supplier Reputation : Investing in forged pipe caps from a reputable supplier is essential. Well-established suppliers adhere to industry standards and rigorous quality control processes, ensuring your caps meet specifications and are free of defects. Working with a reliable supplier minimizes the risk of premature failures, helping safeguard the integrity of your high-pressure piping system.

Why Partner with Nufit Piping Solutions

- Wide Range of Materials : We offer forged caps in stainless steel, carbon steel, and alloy steels, ensuring you find the perfect match for your specific fluids and operating pressures.

- Strict Quality Control : Forged pipe caps often operate under critical conditions. Our meticulous sourcing and testing practices guarantee your components can handle the demands placed upon them.

- Expertise & Support : Our team is here to guide you on material selection, sizing, and best practices to make informed decisions for your high-pressure systems.

Don't Compromise When it Counts

High-pressure systems demand the best, and forged pipe caps are a key part of the equation. Contact Nufit Piping Solutions today at sales@nufitalloys.com to discuss your project and let us help secure your operations with the strength and reliability of our forged solutions.