In industrial piping systems, ball valves are widely used to offer the best flow control and are valued for their efficiency. These basic elements are widely employed across different sectors such as oil and gas, chemical, water, and others. However, the manufacturing process of ball valves is not as straightforward as one would imagine. One of the most important steps in this process is annealing which is very important in determining the quality, strength, and efficiency of the final product.

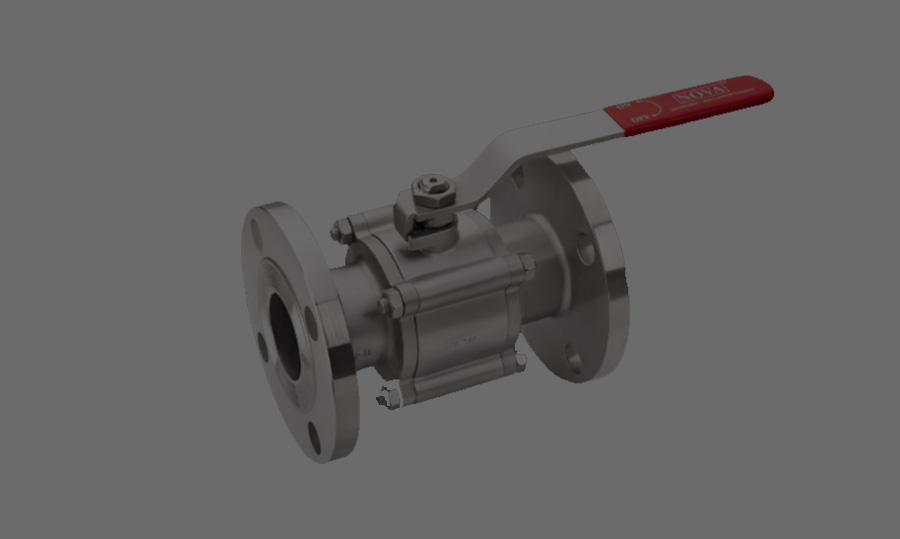

However, in order to proceed to the annealing process, it is important to first know what ball valves are and why they are so popular. A ball valve is a type of rotary valve that rotates a quarter turn and has a spherical disc that is hollow, perforated, and rotates on a central axis. The valve is open when the ball’s hole is parallel to the flow and closed when the ball is rotated 90 degrees by the valve handle.

Ball valves are one of the most used valves due to their low torque and the fact that they can offer a very good shut-off. They are also very durable and long-lasting and this makes them to be the most preferred valves in industries that have high demands

The act of annealing ball valves is essential in improving the performance, service life, and reliability of the valves. The process of heat treatment is known as annealing, which involves heating the valve components to a particular temperature and then cooling them down. It also helps to release internal stress, to optimize the structure of the material, and to increase its ductility. Therefore, the annealed ball valves have improved wear, corrosion, and mechanical properties making them suitable for harsh services. This treatment makes it possible for the valves to be used in conditions that are very harsh such as high pressure and high temperatures and still perform effectively. Annealed ball valves are most important in industries where the working conditions are severe since the process greatly enhances the life span of the valves, cutting on costs of maintenance and losses due to frequent breakdowns.

The heat treatment process of the ball valves involves a number of steps to get the right material properties. First, the valve components are heated to a temperature that will allow recrystallization of the material and this temperature will depend on the type of material. For instance, stainless steel ball valves are normally heat treated at temperatures of between 1,900°F and 2,100°F (1,040°C to 1,150°C). Once the desired temperature is attained the components are kept at this temperature for a certain time to enable the microstructure to solidify. The last stage is the cooling stage, which can be conducted slowly in the furnace (furnace cooling) or by using the quenching method in air or water depending on the material and the properties that are required. The rate of cooling is well regulated to ensure that the formation of undesirable microstructures that would compromise the strength of the material is not realized. The type of annealing that is used depends on the composition of the material, the mechanical properties that are desired, and the application of the ball valves

Many industries benefit from using annealed ball valves since they are more durable and perform better. In the oil and gas industry where the valves are subjected to high pressures, temperatures, and corrosive atmosphere, the annealed ball valves provide better wear and corrosion resistance thus guaranteeing safety and reliability. The chemical processing industry also requires annealed valves due to the fact that the valves are exposed to aggressive chemicals and the environment within the industry is extremely harsh. Furthermore, the power generation sector especially nuclear and thermal power plants gets to enjoy the use of the annealed ball valves since they are capable of handling high stress without breaking down. Water treatment plants that use valves to treat different types of water at different pressures also prefer annealed ball valves because of their long service life and low maintenance requirements. In these industries, the application of annealed ball valves means better productivity, less time off, and less expenditure on maintenance.

As noted, annealing has several advantages, but it also has some drawbacks and issues that have to be taken into account to achieve positive results. Another major issue is the control of the annealing temperature and the cooling rate; if not properly maintained, the microstructure of the valve components may degrade through grain growth or the formation of brittle phases. One factor that may be an issue is distortion or warping which can occur during the heating and cooling processes, particularly in elaborate valve designs. This calls for accuracy and at times the use of fixtures so as to control for dimensions. Moreover, the material composition is also very important for the annealing process; in some cases, for example, in multi-phase alloys, it is necessary to develop special annealing schedules in order to avoid phase separation or embrittlement. In addition, the annealing process has to be incorporated into the manufacturing process sequence in a proper manner in order to prevent the delays and to maintain the quality of the product. However, if properly done, the process of annealing greatly increases the performance and durability of ball valves, making it a critical process in the manufacture of these valves

The annealing process typically involves the following steps :

In the case of any ball valve manufacturer, the quality of the annealing process is something that cannot be compromised. The effectiveness of annealing depends on the temperature, the time it takes for the material to be heated and cooled and the rate of cooling. Even slight variations in the process parameters may lead to the production of a product that does not possess the necessary characteristics of strength, durability, and performance

For instance, if the cooling process is done in the wrong way, it is possible that the metal will develop other internal stresses and the process of annealing will not be useful. Likewise, it is possible that the entire workpiece does not get to the required temperature if the soaking time is inadequate, which will result in different microstructures and possible structural flaws in the valve

In the case of ball valves, the process of annealing cannot be overemphasized because it is a critical step in the manufacturing process. This critical heat treatment process ensures that the valves are strong, long-lasting, and able to withstand the most challenging conditions of the industrial processes. In this way, the process of annealing is one of the most important steps in creating high-quality ball valves that will not fail under stress or corrosion and are easier to machine

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more about Ball Valves and their applications in various industries.