In the complex operations of chemical plants, precision and control over fluid handling are non-negotiable. Among the various tools and components deployed to achieve this precision, needle valves stand out due to their ability to regulate the flow of liquids and gases with remarkable accuracy. Nufit Flanges, a leading needle valve manufacturer and needle valve supplier, highlights how these valves play a critical role in optimizing the performance and efficiency of chemical processing systems.

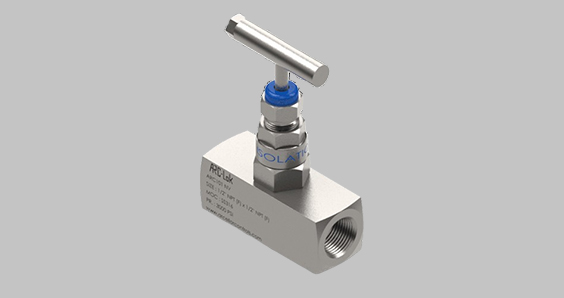

What is a Needle Valve?

A needle valve is a valve with a small opening that can be closed using a needle. This makes it capable of managing the flow with a good deal more precision, though at still quite low rates. The valve has a distinctive design that allows well-controlled fluid discharge, making it perfect for processes demanding very exact flow measurements.

Importance in Chemical Plants

Needle valves are quite important in chemical plants, which require absolute control of the flow rate of different chemicals to guarantee security and efficacy. They are used for accurate dosing, giving without shared reactant addition, and flow controlling of gases in high-temperature, high-pressure environments

Features of High-Quality Needle Valves

- Control With Precision : The most prominent characteristic of needle valves is the precision in adjusting the liquid flow, very useful in handling processes that require regulating the rate of flow. The valve is designed to increase or decrease the flow only very slowly, considerably reducing the risks of hazardous process imbalances or accidents due to sudden changes.

- High-Pressure Capability : High-pressure needle valves are built to withstand high pressures without fail. They are made with detailed materials that can withstand chemicals and the demanding lifestyles that typical chemical plants use. As one of the needle valve suppliers, Nufit Flanges guarantees the compatibility of their valves with different liquids to comply with a broader selection of pipe types.

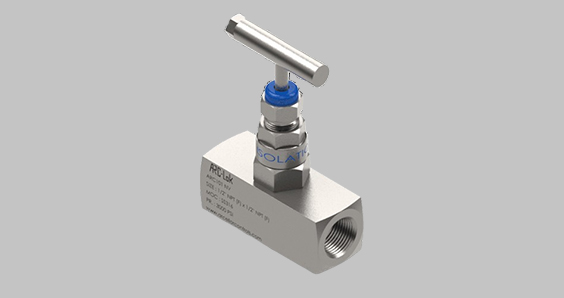

- Compatibility and Versatility : As a prominent needle valve supplier, Nufit Flanges ensures that their valves are compatible with a wide range of fluids and can be integrated into various types of piping systems. The versatility of needle valves makes them suitable for a broad array of applications within chemical plants, including sampling lines, analytical instrumentation, and research applications.

Selecting the Right Needle Valve

- Material Considerations : The choice of material for needle valves is crucial and depends on the type of chemical fluid they will regulate. Materials such as stainless steel, brass, and special alloys are common, chosen for their resistance to corrosion and thermal stability.

- Size and Connection Type : The size of the needle valve must match the requirements of the application, particularly the flow rate and pressure. Connection types also vary, including threaded, flanged, or welded, depending on the existing piping system’s specifications.

- Customization Options : Being a leading needle valve manufacturer, Nufit Flanges offers customization options to meet specific operational requirements. These may include modifications for extreme temperatures, special seal materials, or unique valve body designs.

Conclusion

Needle valves are more than just components in the piping systems of chemical plants; they are critical tools for enhancing process accuracy, efficiency, and safety. By choosing the right needle valve from a reputable needle valve manufacturer and needle valve supplier like Nufit Flanges, chemical plants can optimize their operations and achieve better control over their intricate processes. The investment in high-quality needle valves is an investment in the plant's future, ensuring stability, reliability, and precision in daily operations

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more information about the Needle Valves, and how you can utilise them in chemical plant operations