In the world of industrial piping, buttweld fittings stand out as a fundamental component for ensuring robust, leak-proof connections. As a leading buttweld fittings manufacturer, Nufit Flanges offers a deep dive into the significance of these fittings, their applications, and their essential counterparts in the piping and fabrication industry. This blog explores why buttweld fittings are crucial in various systems and how they work seamlessly with other pipe fittings.

Understanding Buttweld Fittings

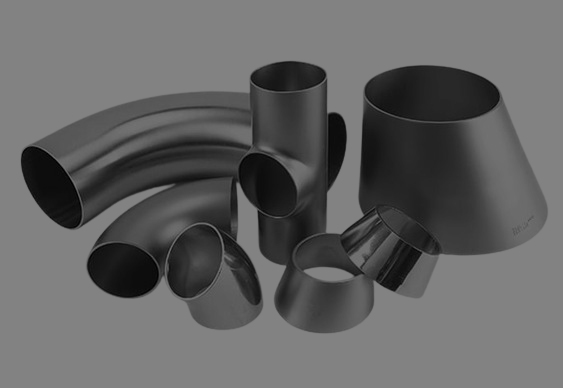

Buttweld fittings are a kind of pipe fitting, that is used to match two pieces of a pipeline together by welding. They are usually used in systems where a welded connection is permanent & can provide a smooth flow within the pipe. Buttweld fittings offer a significant advantage over other types of pipe fittings because of their smooth directional change.

Types of Buttweld Fittings

Buttweld fittings include a variety of shapes and sizes, each designed for specific applications

- Elbows : Used to change the direction of the flow in a piping system.

- Tees : Branch connections that allow fluids to be mixed or divided, facilitating flow from multiple directions.

- Reducers : Connect pipes of different diameters, ensuring a smooth flow between sections.

- Caps : Provide a sealed end to a pipe, protecting the system from external contaminants.

Fabrication and Installation

Nufit Flanges is a premier buttweld fittings manufacturer that manufactures all these fittings ensuring precision and manufacturing excellence to provide the best quality. This is made by heating up the pipe and using force to form it into a shape, without adding any materials. This ensures that the pipe retains its structural integrity. This type of fitting requires welding and provides a stronger connection especially for high-pressure applications. These are just a sample of the type of technical welding which must be done properly or the building can suffer from thermal collapse. A skilled technician is required for welding where rigorous testing is part of every installation

Essential Counterparts to Buttweld Fittings

While buttweld fittings are indispensable, their functionality is enhanced by their counterparts in piping systems

- Flanges : Allow for disassembly and flexibility in high-pressure and high-temperature environments. They work alongside buttweld fittings to provide access for cleaning, inspection, or modification.

- Gaskets : Seal the joint between flanges, preventing leaks in the system. Gaskets complement the solidity of buttweld fittings by ensuring that all connections are secure and leak-proof.

- Valves : Control the flow and pressure within the system. Buttweld fittings are often used to connect valves in a seamless manner, integrating control mechanisms into the piping structure.

- Piping and Tubing : The primary components that are connected using buttweld fittings. The compatibility of the pipe material with the fitting is crucial for ensuring a successful weld and a functional piping system.

Why Choose Nufit Flanges?

Choosing the right buttweld fittings manufacturer is critical to ensuring that your piping systems are robust, efficient, and safe. Nufit Flanges stands out in the industry for

- High-quality materials and products : At Nufit Flanges, we have a wide range of buttweld fittings that are meticulously designed and processed using the best raw materials. This applies equally to premium-grade steel, alloy, and other materials necessary for industry-leading levels of strength, rust resistance, and performance in the harshest conditions. Every product is aggravatingly tested and re-tested to weather through the torque of high-pressure environments, all while standing up against corrosive compounds, making sure these products run long and strong.

- Expertise in fabrication and installation : Nufit Flanges has extensive experience in buttwelding from both a fabricating and an installing perspective. Expert engineers and experienced technicians work together, using cutting-edge manufacturing techniques and technology to produce high-quality fittings with precision. Furthermore, we offer specific installation instructions and assistance on-site to make sure the fittings are welded in well enough to keep your piping system uses safe and effective. Our experience also offers a comprehensive knowledge of the different industrial norms which is very important for full compliance and security in every project.

- Comprehensive range of fittings suitable for various applications : Nufit Flanges provides a broad array of buttweld fittings that apply to numerous industrial applications and industries. Our portfolio ranges from standard elbows, tees, and reducers to special caps or custom designs, tailored to the specific requirements of each industry - may it be oil & gas, water treatment, chemical processing, food & beverages, etc. With such a wide range of sizes and options, there is the right connection for virtually every customer need - to make system design and implementation all that much easier.

- Commitment to customer satisfaction and technical support : Customer satisfaction is one of the most important for likewise Nufit Flanges. Our personalized service, quick response to inquiries, and technical support set us apart from a simple “matchmaking” agency. We offer maintenance suggestions and tips to keep our products functioning as optimally as possible through the lifespan of the machine, in addition to troubleshooting when targeted with a problem. Our responsive customer service team is always there to address any questions or concerns, providing each client with all the support he/she needs for well-managed and dependable operations.

In conclusion, buttweld fittings are essential components in any piping system, providing a reliable and strong connection that enhances the system's overall functionality and integrity. Paired with their counterparts like flanges, gaskets, and valves, these fittings ensure that industrial systems operate smoothly and efficiently. At Nufit Flanges, we take pride in manufacturing top-quality buttweld pipe fittings that meet and exceed industry standards, ensuring our clients receive the best solutions for their piping needs

You can Contact Nufit Flanges at sales@nufitalloys.com to learn more information about the Buttweld Fittings, and how you can utilise them in your operations